5052 aluminum plate is AL-Mg alloy aluminum plate, magnesium is the main alloy element in 5052 aluminum plate, is the most widely used rust resistant aluminum, this alloy has high strength, especially with fatigue strength: High plasticity and corrosion resistance, can not be strengthened by heat treatment, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability, bad machinability, polishing.

Aluminum - magnesium alloys also contain small amounts of manganese, chromium, beryllium, titanium, etc. In addition to a small amount of manganese in the alloy, most of the formation of MnAl6. The role of chromium in 5052 aluminum plate is similar to that of manganese, which can improve the stress corrosion cracking resistance, improve the strength of matrix metal and weld, and reduce the welding crack tendency, but its content is generally less than 0.35%.

| Grade | 1000- 7000 Series |

| Temper | O-H112,T351-T851,T3-T8 |

| Type | Plate |

| Application | solar reflector, wall, furniture,cabinets |

| Width | 20-2500mm |

| Surface Treatment | Coated |

| Alloy Or Not | Is Alloy |

| Place of Origin | Jiangsu |

| Model Number | 5086 5083 6061 7003 1060 5052 5754 7075 etc |

| Tolerance | ±1% |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Delivery Time | 8-14 days |

| Material properties | Rust resistant, hard, forged, super hard |

| service | 24 hours a day |

| Finish | Polished Bright Finish |

| processing craft | Quenching and tempering |

| Coating | Printing Screen Printing |

| ductility | High elongation |

| Technique | high strength, good usability, strong corrosion resistance |

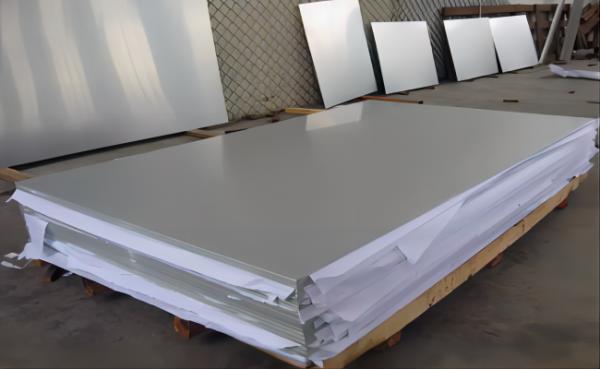

| Package | Standard Seaworthy Packing |

| processing technology | processing technology |

| Advantage | Weather-proof |

Product Details